Technologies and Services

Learn about the SSI Core™ and our engineering services

SSI Core™ Water Treatment System

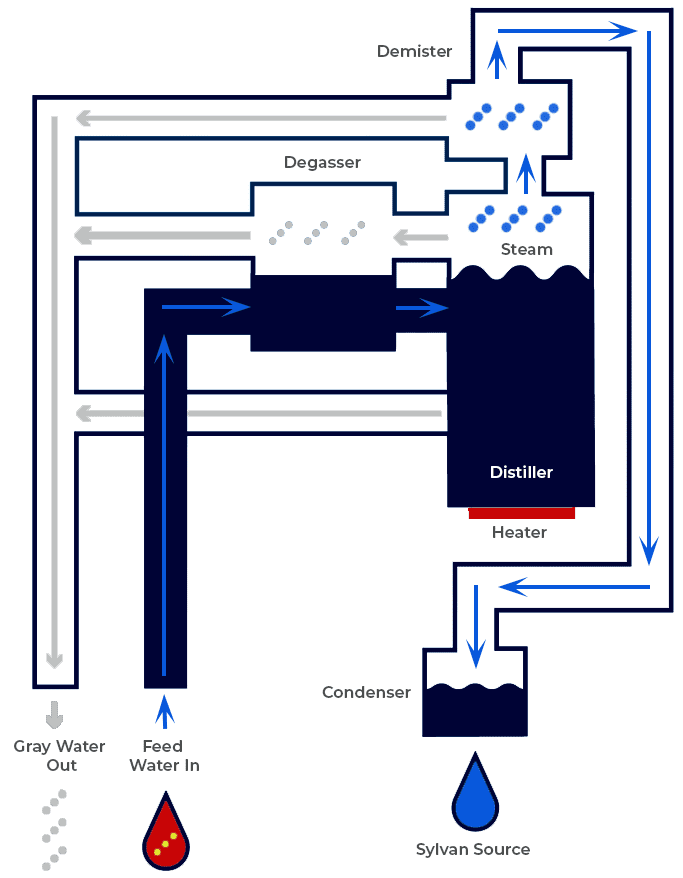

The SSI Core™ for industrial and municipal systems consists of multiple stages that boil water to create steam and then condense the steam to create clean water. The energy to drive the first stage can come from a variety of sources (including steam, natural gas, flue gas, solar thermal, geothermal and recoverable energy or waste heat). The energy to drive the subsequent stages comes primarily from the heat of condensation of the steam that was created in the previous stage. SSI’s ability to reuse the energy with proprietary technology (not based on the physics of heat exchangers) enables significant system efficiencies, low CapEx and low OpEx compared to all conventional technologies Reverse Osmosis (RO), Multi-Stage Flash evaporation/Millions of Gallons per day (MSF/MED), evaporators).

The SSI Core™ is able to reduce a broader range of contaminants, and higher concentrations of contaminants than other technologies in comparable plants. This is in large part due to the integration of three water treatment technologies in a single, thermally balanced system. SSI’s industrial-municipal systems generally require pre-treatment for the applications targeted. A range of standard pre-treatment capabilities to support optimization of the SSI Core™ may be used such as:

-

Ion exchange (many conventional produced water applications)

-

Weak acid (seawater)

-

Precipitation (more complex industrial waste streams)

1) Degassing

Water is heated to near boiling inside the degasser. Pre-heating allows dissolved gases and organics to vaporize. Counter-flowing steam, air, or gas discharges these contaminants out of the degasser. The degasser waste stream is collected and condensed for disposal.

2) Distillation

After degassing, water moves into the distiller where it is converted into steam. The SSI Core™ operates close to atmospheric pressure with a small number of low-pressure pumps in the entire system. However, it is also possible to configure SSI systems with vacuum.

3) Demisting

After leaving the distiller, steam and mist droplets enter the demister, where they are separated using a patent-pending process. Droplets are discharged from the demister.

Ultra-clean steam then condenses into product water.

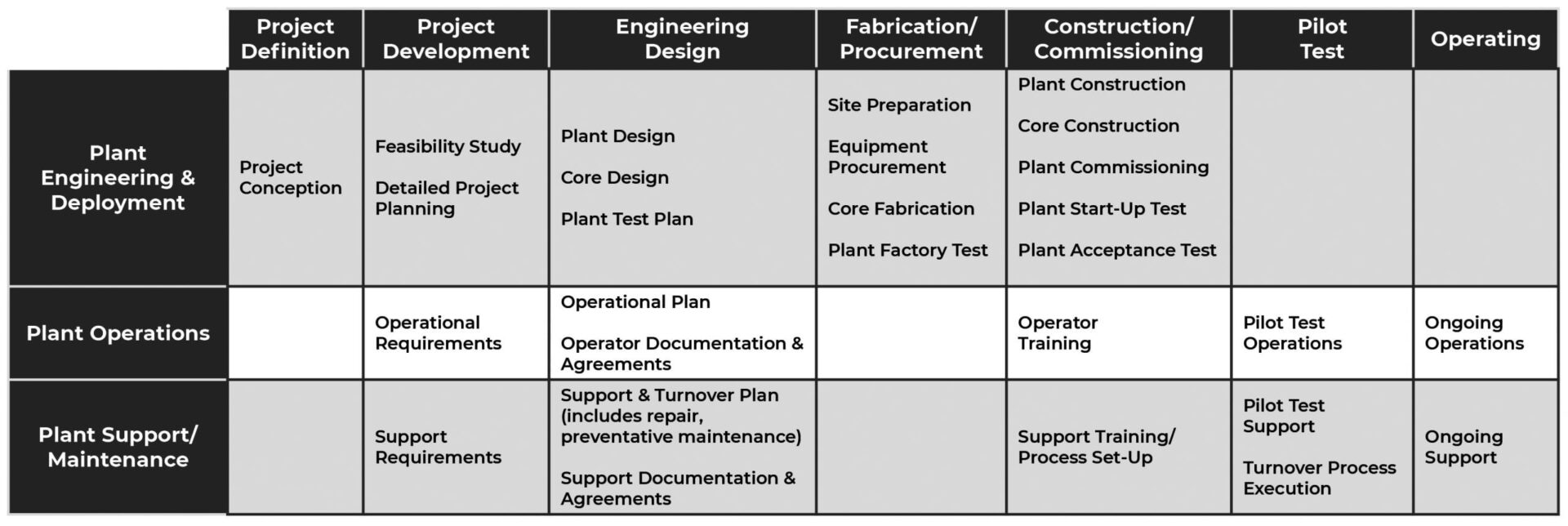

Engineering Services

Health, Environment and Safety (HES) policies and procedures in all applications are an important focus for SSI across the value chain

SSI provides engineering services to support the design and implementation of its energy systems and water treatment plants. In most cases, SSI will take the lead as “Prime” in plant deployments, and in all cases, SSI will work with several key partners across the value chain.