Industrial-Municipal Systems

Overview and benefits

Technology

The SSI Core™ water treatment system – multiple patents granted and patents pending

-

Produces ultra-clean water from contaminants up to 200,000 ppm TDS with saturated volatile and non-volatile gases

-

Combines distillation with degassing (steam, gas or air stripping) and demisting

-

The pilot plant has reduced 147,000 ppm TDS to 14 ppm TDS in a single pass

-

The SSI Core™ water treatment system is capable of concentrating waste streams to a heavy brine that crystallizes upon cooling – effectively providing Zero Liquid Discharge (ZLD) in a standard or typical configuration

- In Pilot Plant Testing for a cooling tower blowdown application, the SSI Core™ product water was consistently at or below 1ppm TDS with a basic configuration.

Breakthrough heat capture and transfer – multiple patents granted and patents pending

-

Able to capture heat (thermal energy) from a wide range of sources

-

Significant thermal transfer efficiency advantages

-

Does not rely on heat exchangers

-

Improved heat process control

Pretreatment

-

Industry standard pretreatment methods can be used with the SSI Core™ water treatment system for all applications

-

SSI’s proprietary pretreatment technology enables cost-effective recovery and separation of waste streams into pure elements

Applications

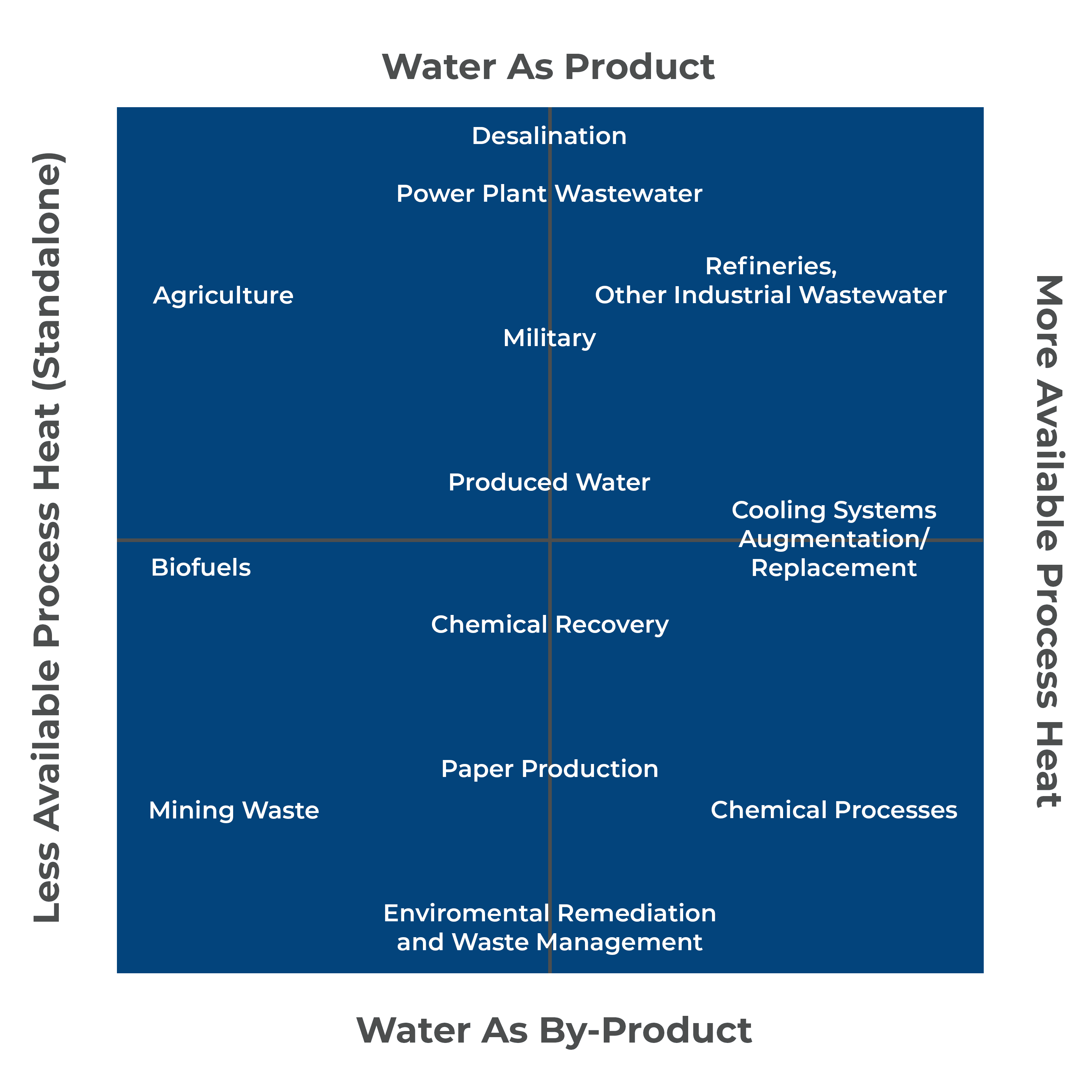

SSI’s technology may be applied to the benefit of several water treatment applications, including but not limited to those indicated below. In addition, the company has developed IP and technology for energy transfer, storage and management and the treatment of other reagents (non-water).

Energy Efficiency

The SSI Core™ water treatment system utilizes a high-efficiency thermal transfer mechanism rather than conventional heat exchangers for heat transfer, both enhancing efficiency and reducing costs and footprint. SSI’s patented and patent-pending thermal transfer mechanisms offer significant technical advantages including:

-

Superior heat transfer coefficients

-

Enhanced mass transfer and improved geometry with no pumps and no potential clogging

-

Completely passive, sealed configuration enabling wider use of available heat sources including waste heat

Gain Output Ratio (GOR) is a common measure of thermal system efficiency and it is defined as the amount of product (treated) water produced per unit of steam. GOR has a strong effect on both CapEx and OpEx. SSI’s GOR has been benchmarked at 26 for an oil and gas application and 25 for a seawater desalination application. Conventional thermal systems are generally in the 6-12 range. SSI is able to operate with lower temperature losses between stages and across the system which contributes to the high GOR.

Energy Flexibility

SSI’s system is very flexible in the heat sources it can utilize including:

-

Solar

-

Nuclear

-

Geothermal

-

Recoverable energy (or waste heat) from industrial processes

-

Fossil fuels – direct fired

-

Steam

Availability of waste heat from any industrial process offers significant additional reductions in energy costs/footprint with

the SSI system.

SSI’s systems are an excellent fit with renewable energy sources.

See additional examples of integration with renewable and recoverable energy sources

Economics

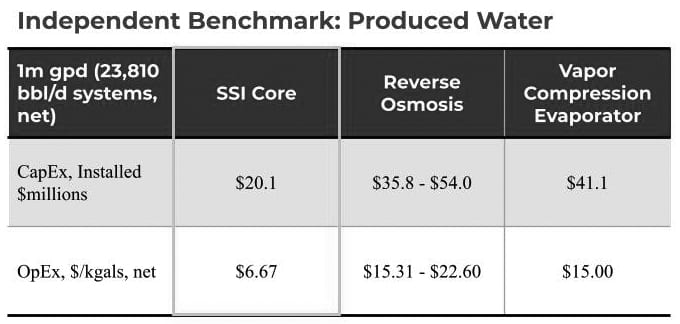

SSI has participated in a number of independent benchmarks, some led by large industrial customers. In all cases where there has been a comprehensive view of the plant with all costs taken into account, and with evaluations conducted by independent experts who are able to validate all claims and positions, SSI has always been more competitive in CapEx and OpEx than any of the conventional or emerging technologies benchmarked.